Product Development

We integrate specialized skills from each part of the design design process to provide comprehensive service, from product development and production to after-sales support.

We design refrigeration and air conditioning systems at the foundation of customer equipment. To satisfy our customers' requirements, we solidify system fundamentals, such as determining refrigeration circuit configuration, examining the order of placement of major components and control methods, and reviewing the mass balance and heat balance of each circuit.

■Refrigeration circuit design technology (Moriel diagram)

■Control and measurement technology for ultra-low temperature and high temperature fluids

■Analysis technology using material balance and outgas evaluation

'-120℃ dew point sensor, ion chromatography, gas chromatography, used in ultra-small super clean rooms

■Comparative evaluation of energy saving efficacy and performance specifications based on intensity calculations

■Design and selection of a wide variety of heat exchangers using heat transfer engineering

■Support for various safety specifications (SREMI standards, CE marking, etc.)

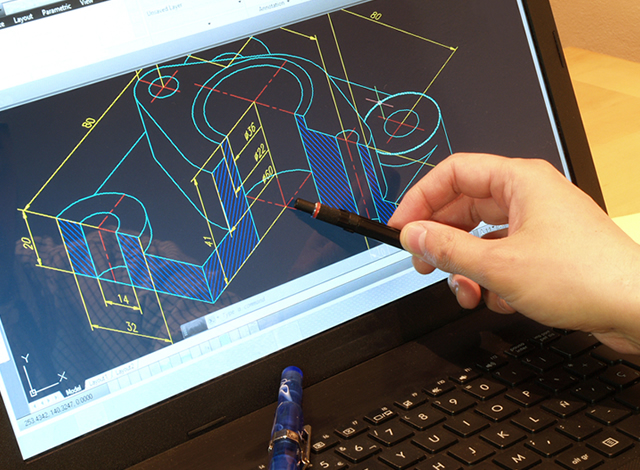

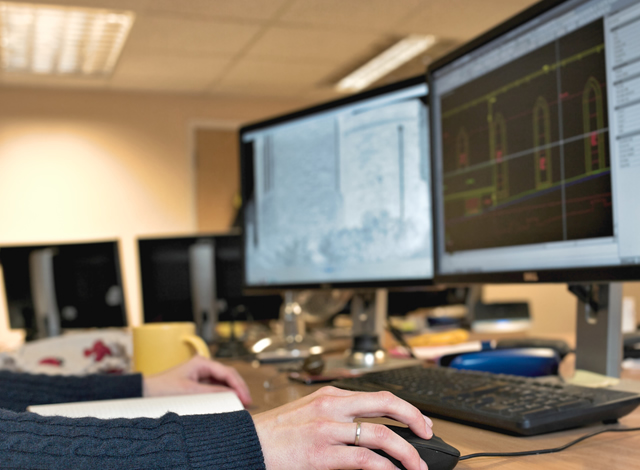

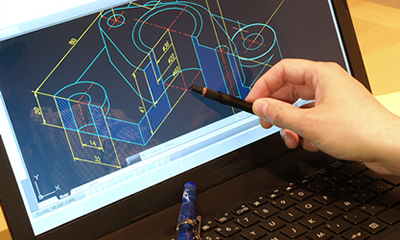

Mechanical Design

We create drawings using 3D CAD and perform a wide variety of calculations, such as strength and earthquake resistance. Services offered include designing the layout of structural components and piping using 3D CAD, and calculating the strength of sheet metal components.

■Structure optimization accomplished with weldless and modular design

■Equipment selection and evaluation based on expected lifecycle settings (component-level reliability testing)

■Fatigue life diagnosis through stress amplitude measurement

■Strength analysis of machine parts using CAE

■Design and drawing for sheet metal and machine parts

■Design for molds, processing jigs, and transportation jigs

■Corrosion protection of steel materials and coating / surface treatment technologies

Production Design

This is an advanced equipment design process, in which various simulations are conducted prior to manufacturing to carefully check and eliminate potential failures. Product reliability can be increased by performing thermo-fluid simulations for thermal air conditioning, as well as verifying air flow and temperature prior to manufacturing.

■Reliability design technology

■Design technology that takes productivity and assembly into account (productivity simulation)

■Analysis techniques for thermal fluid analysis, structural analysis, magnetic analysis, etc.

■Evaluation of design products

■Measurement technology for temperature, humidity, vibration, and electrical properties

■Expertise in such processes as machine processing, sheet metal fabrication, plastic molding, etc.

■Design of efficient production processes with consistent quality control

■Design technology for production equipment and jigs

Hardware Design

In this process for electronics design, we perform detailed internal design work for equipment, such as electrical circuit design, selection of components, and control panel layout design.

■Preparation of specification requirements documents

■Power consumption calculation for compressors and other drive equipment

■Selection of control components

■Electrical system diagram (block diagram) creation

■Control panel rough size estimation

■Control panel internal heat calculation

■Various types of simulations

Software Design

This process involves the creation of software for use in equipment operation. We perform sequence control, interface with customer equipment, design interfaces for equipment operation, and detect system anomalies.

■Preparation of specification requirements documents

■Creation of control system diagrams

■Creation of operational timing charts

■Operation flow and state transition diagram creation

■Creation of abnormal handling lists

■Test plan development

■Confirmation of test result validity